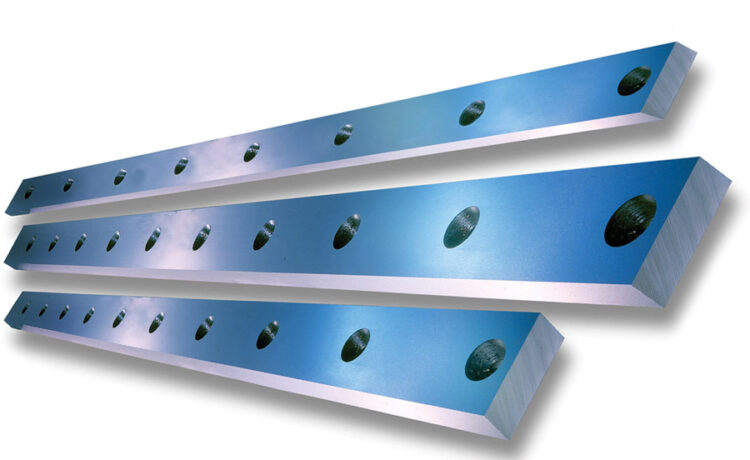

For craftsmen of various industries, guillotine blades form a necessary and indispensable part of daily work. While the most common association involves using them as part of heavy-duty equipment, typically for cutting sheet metal or other durable materials, their real application extends far beyond that. Today, we’ll explore the primary uses of guillotine blades and knives, as well as their significance in versatile industrial contexts.

What Industries Are Guillotine Blades Used In?

Cutting material of various toughness and density requires the right tools for the job. In many industries, that function is performed by guillotine blades. Their straight-edge design excels in cleanly cutting material in vertical motion with superb precision. Want to know which industries utilize guillotine blades the most? Take a look below.

Paper Industry

Guillotine blades have wide applications in the paper industry, where they’re used for the cutting and processing of various materials, including paper and cardboard. Manufacturers producing these goods rely on the blades’ versatility, as they often need to cut sheets of different shapes and sizes. A good quality guillotine blade will maintain its sharpness and ability to cut edges cleanly with no tearing for longer than shear blades or circular knives would in this context.

Food Processing

Guillotine blades are the top choice of precision equipment in the food processing industry, where they are used to cut meat, fish, and other products. In this sector, reducing waste is paramount, thereby necessitating the use of sharp and precise blades. Also, to comply with sanitation and hygiene regulations, the edges require regular cleaning, making guillotine blades even more efficient due to their straightforward shape.

Textiles and Clothing

The textile industry also heavily relies on guillotine blades and their ability to cut fabrics with extreme precision. The prestige of exclusive garments is often predicated on impeccable quality and make, leaving no room for error, fraying, or damage in the production process. High-quality guillotine blades offer precisely that kind of reliability needed to maintain the integrity of the final product.

Recycling and Waste Management

Guillotine blades play an important role in waste management and contribute to environmental sustainability efforts. Everyone produces trash – it’s an inescapable aspect of daily life. The onus of dealing with what’s left falls to waste management plants. When you consider the unimaginable heaps of trash we produce, efficiently processing it all in one piece would be a Herculean task. That’s where guillotine blades come in, with their primary task being to reduce the size of what ends up in landfills and processing plants into more manageable, recyclable bits.

Metal Processing

When working with something as heavy-duty as metal, shaping or cutting it requires an equally strong implement. Guillotine blades are so powerful that they can cut steel sheets and metal components with precision, which is vital for maintaining the quality and specifications of final products.

The Takeaway

Guillotine blades are indispensable across various industries. Their precision, durability, and versatility have cemented them as staples in the industrial world – provided they’re made out of high-quality tool steel or alloy in the first place. For that reason, always rely on a trusted provider of industrial equipment to comply with applicable standards.